Research & Development

Research Institute Overview

Since the establishment of the Technology Research Institute in 2001, we have been designing and manufacturing hot, cold, and complex forging molds to meet customer quality requirements. We focus on the research and development of automotive parts such as transmissions, engine, chassis components,and mechanical parts.

Our R&D efforts extend to the development of new materials, new processes, and innovative technologies, including research on hydrogen vehicles and other future industries. We are committed to continuous technological innovation to strengthen our competitive edge and lead a sustainable future.

Research & Development History

2022

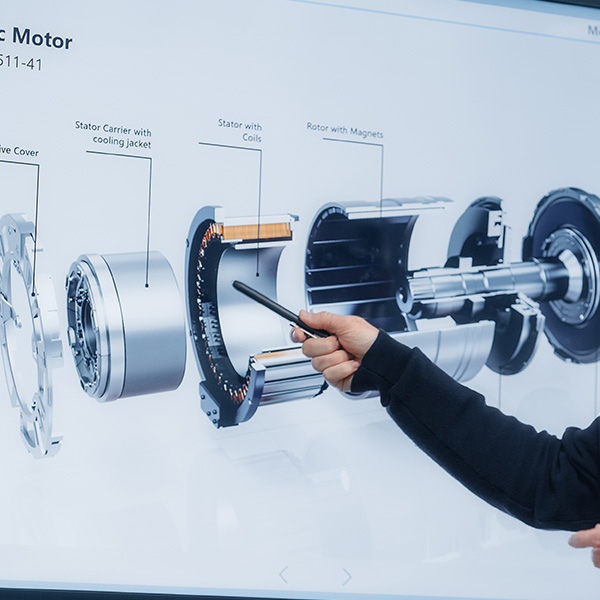

Developed hot forging for Electric Vehicle Rotor Shaft

2021

Developed cold forging for Hydrogen Vehicle Rotor Shaft

2020

Relocation of the Technology Research Institute (to Anyang)

2019

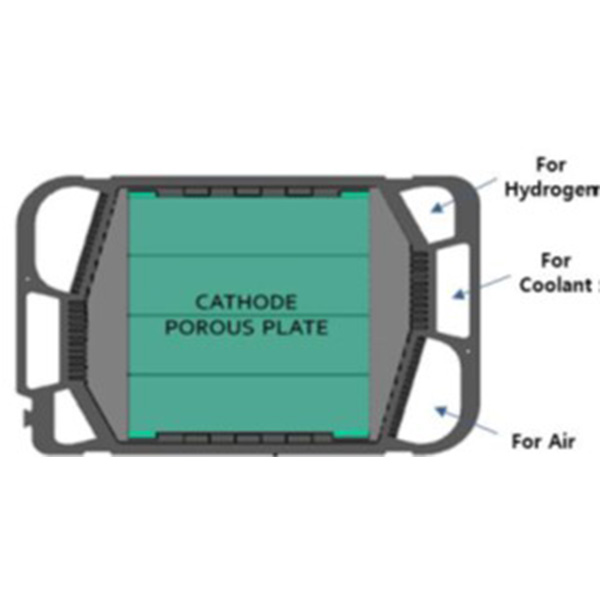

Pre-development of manufacturing process technology for metal separator molding for next-generation hydrogen fuel cell vehicles

2015

Developed Transfer Driven Gear tooth-shaped forging sealed automation process

2011

Applied hot forging automation process for Differential Drive Gear

2007

Registered a new patent for [Hollow Shaft Spline Forming Cold Forging Process]

2006

Co-developed non-quenching steel for hot-forged chassis components (with Hyundai Mobis technical exchange)

2003

Developed Transfer Driven Gear tooth-shaped non-machining (non-cutting) forging process

2001

Established the Technology Research Institute (in Ansan)

Continuous Technological Innovation

Leading a Sustainable Future

Future-Forward Technological Competitiveness

Research and Development Areas

Forming Technology Methods

Hot ForgingCold Forging Complex Forging (Hot Forging + Sizing)

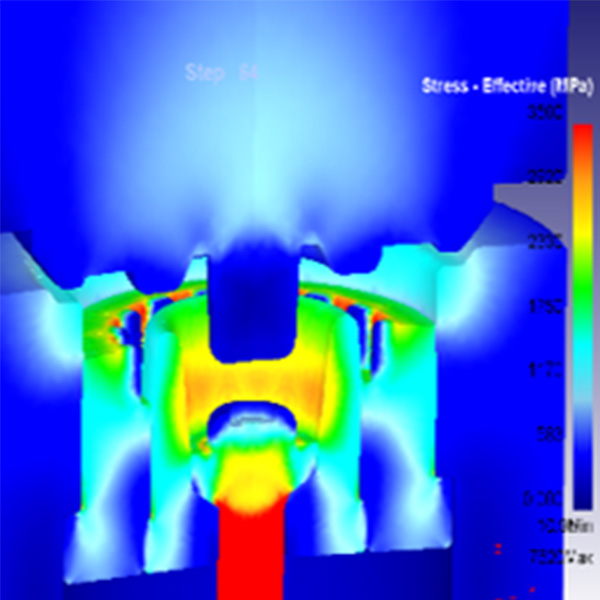

Design/Analysis Research

Forming Load and Stress Analysis Mold Life Prediction Metal Flow Analysis

Future Mobility Component Development

Rotor Shaft(Electric Vehicles, Hydrogen Vehicles) Metal Separator Plate(Hydrogen Vehicles)